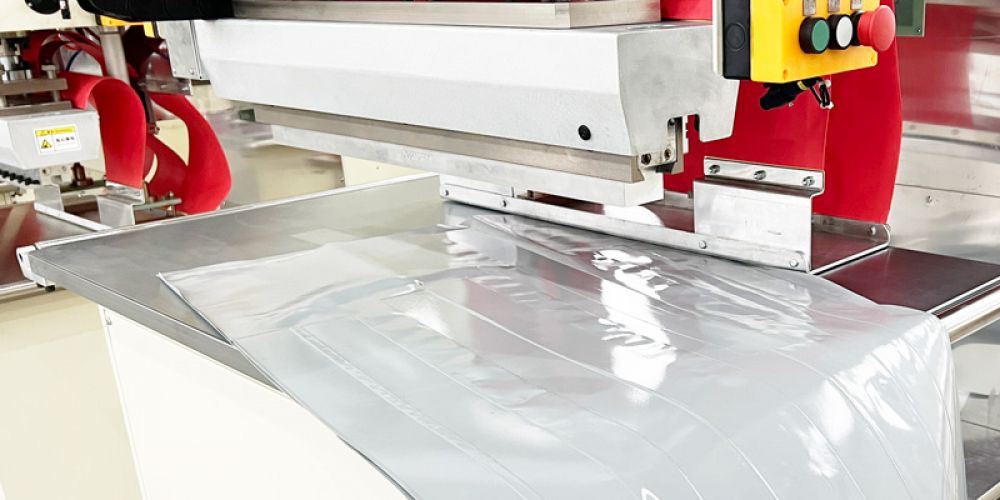

The high frequency welding machine converts the current in the induction coil into a high frequency alternating magnetic field through high frequency electromagnetic induction, so that the molecules inside the film move rapidly, friction generates heat, heats the film, and finally achieves the purpose of melting.

In the melting state of the film material, appropriate pressure is applied to make it bond. In the welding process, temperature control is very critical, and it is necessary to adjust and control according to the nature of the material and the process requirements to ensure the welding quality.

Film welding machine welding speed, simple operation, high welding quality, wide range of application, so it is widely used in packaging, medical, automotive and other fields of product manufacturing process.

Cost-Efficiency: Less frequent repairs and product returns mean savings in the long run.

Investing in a quality HF welding machine might seem hefty initially, but the returns in terms of reduced operational costs are undeniable.

Versatility: From inflatable products applications to outdoor awnings and indoor shades, the applications of HF Welder are vast and varied. They offer solutions that cater to a diverse range of needs.

Eco-friendly: Modern HF welding techniques, especially when compared to some traditional methods, are more environmentally friendly, producing fewer waste materials and consuming less energy.

Understanding these benefits, it's evident that transitioning to HF welding, especially with the quality assurance of PUXIONG Welding Machines, is the future of PVC/PVDF fabric manufacturing.