1. Overview and characteristics of membrane structure

As an important branch of modern spatial structure system, membrane structure is a brand new architectural structure form, which integrates architecture, structural mechanics, fine chemical engineering, material science, computer technology, etc., drawing on the achievements of modern plastic arts and technical aesthetics, its curved surface can be changed as the architect's design needs, and its appearance is novel and unique. The interior space gives people a dreamlike feeling, largely satisfies the modern aesthetic concept, and becomes a new style of modern architecture.

At the same time, it has the characteristics of making full use of sunlight, air and integration with nature, which is in line with the major strategy of "environmental protection and sustainable development" currently advocated, and also provides a broad space for the development of high-tech ecological buildings, and is favored by advocates of green building movement around the world. Will become the 21st century "green building system" darling.

2. Development history of inflatable membrane structure

With the development of high-strength building materials, mathematical mechanics, structural analysis, production and installation technology, and computer technology, membrane structure system continues to evolve, and can generally be divided into inflatable membrane, tension membrane, skeleton membrane and cable dome membrane structure and other structural systems. The aerated membrane structure is the main form in the initial stage of membrane structure development.

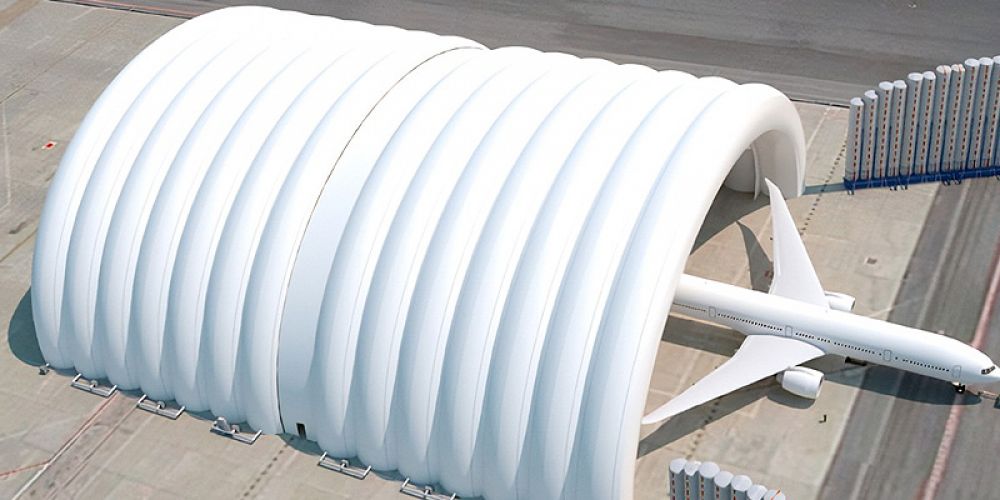

The inflatable membrane structure uses the sailing principle to support the membrane surface by the Air pressure in the membrane, and can be divided into Air supported membrane structure (air-supportedmembrane)~D air bag membrane structure (air-inflatedmembrane). The air bearing membrane structure is to fix the edges around the membrane surface. Pressure is applied to the interior of the membrane building to bulge the membrane surface to the design space curved surface, and the internal and external pressure difference is maintained to press the membrane surface to ensure the rigidity, thus maintaining the shape and resisting the load.

The balloon membrane structure is inflated in a specific shape of the air bag to form a structure or component with a certain stiffness, and thus bear the load. The advantage of the air bag type compared with the air bearing type is that the indoor atmosphere is normal pressure gas environment, which avoids the discomfort caused by overpressure.

In 1917, the British W, Lanchester proposed the idea of using the blower to blow the expanded film cloth as a field hospital and applied for a patent, but at that time due to the limitations of technical conditions, it was only an idea and did not become a reality.

In 1946, American WalterBird built the first inflatable membrane structure for the US military to make a spherical Doppler radar dome (DopplerRadome) with a diameter of 15m and a height of 18,3 m, which can protect radar from climate invasion and allow radio waves to pass unblocked, thus putting the patent separated by 29 years into practice. At that time, glass fiber was used as the base cloth of chloroprene rubber as the coating film.

Between 1950 and 1970, a large number of similar domes were built successively in the United States and Germany, with a maximum diameter of 60m.

In 1957, he covered his swimming pool in an inflatable membrane structure, and made a detailed introduction in an American magazine, so that the inflatable membrane structure was known to the world.

In 1967, the first International Conference on inflatable structures was held in Stuttgart, Germany, which undoubtedly injected stimulants into the development of inflatable membrane structures. Then a variety of inflatable membrane structures mushroomed.

1970 International Exposition Osaka, Japan (EXP070, Oska). Japan), began the transformation of rigid structure to flexible structure, becoming a milestone in the history of membrane structure.

3. Development and classification of membrane materials

The development of membrane structure is inseparable from the emergence of new membrane materials, and the development of new membrane materials has greatly promoted the further development of membrane structure. Membrane materials are mainly developed with the progress of modern fine chemical technology. The early membrane material is based on polyvinyl fluoride as the surface coating and polyester fiber as the substrate membrane, which is now known as Class C membrane (PVC/PES), and its architectural and structural mechanical properties are not ideal.

In the 1960s, glass fiber fabric film technology has been greatly developed and has been widely used, but the surface coating is still polyethylene-based, now known as class B film. At the same time, the manufacturing technology of Class C membrane materials has been continuously improved, and the structural and architectural characteristics have gradually improved. In the early 1970s, the DuPont Company in the United States successfully developed A polytetrafluoroethylene (chemical name PTFE, trade name Teflon) surface coating material with excellent building performance, while the glass fiber fabric film technology is becoming mature, making the modern fabric film coated with glass fiber based cloth PTFE came out, now known as A class A film, Its high strength, good self-cleaning and other excellent properties have been widely used in engineering.

4. Development of membrane structure and membrane materials in China

In the early 1980s, China built the first inflatable membrane structure - Shanghai Industrial Exhibition Hall, which is a cylindrical air bearing membrane structure, the substrate of the membrane material is nylon fabric and the coating is polyethylene resin.

In 1997, the construction of Shanghai Stadium marked that modern membrane structure entered the stage of application and development in China. The stadium house cover takes the shape of a saddle, it is a roofing layer of 57 umbrella like cable structure, which is covered with high technical material sheery-fill film layer, have a far-reaching impact on the development of our country's membrane structure.

In 2000, Qingdao Yizhong Stadium, the first self-designed and completed large-scale membrane structure project in China, was built, consisting of 60 conical membrane units, covering an area of about 30000m3.

The envelope structure of the main stadium of Beijing 2008 Olympic Games "Bird's Nest" and the National Aquatics center "Water Cube" are both air-bag membrane structure, and the complex buildings are gridded and the form of small air-bag membrane is adopted, which provides reference value for China to master the construction of long-span air-bag membrane structure (air-bearing membrane structure).