Membrane Structure Architecture

As a new architectural form, membrane structure buildings began to emerge in the 1950s. The U.S. Pavilion at the 1970 Osaka World Expo featured glass fiber fabric coated with polyvinyl chloride (PVC) resin, marking the rapid development of membrane structure applications.

Advantages of Membrane Structures

Membrane structures weigh just 1/30th of traditional buildings and overcome challenges faced by conventional structures in large-span, unsupported constructions. Their lightweight, flexible designs, ease of fabrication, and quick installation have led to widespread global adoption.

Materials for Membrane Structures

Architectural membrane materials fall into two categories: woven (e.g., PVC and PTFE membranes) and non-woven. By the late 20th century, a new material—ethylene tetrafluoroethylene copolymer (ETFE)—was introduced.

PTFE Membrane Structure Case Studies

-

Shanghai Stadium (1997)

- Hosted the 7th National Games of China.

- Featured a saddle-shaped, steel-space roof covered with 36,000 m² of milky-white PTFE membrane—China’s first large-scale permanent membrane structure.

-

Foshan Century Lotus Sports Center (2006)

- 36,000-seat stadium with an 80-panel cable-membrane roof.

- Covered by 53,000 m² of PTFE membrane (expanding to 70,000 m² when unfurled), making it one of the world’s largest cable-membrane structures.

-

Cangzhou Stadium (2014)

- Main venue for the Hebei Provincial Games.

- Designed as a "lotus pedestal" with 20 translucent PTFE membrane petals covering the roof.

-

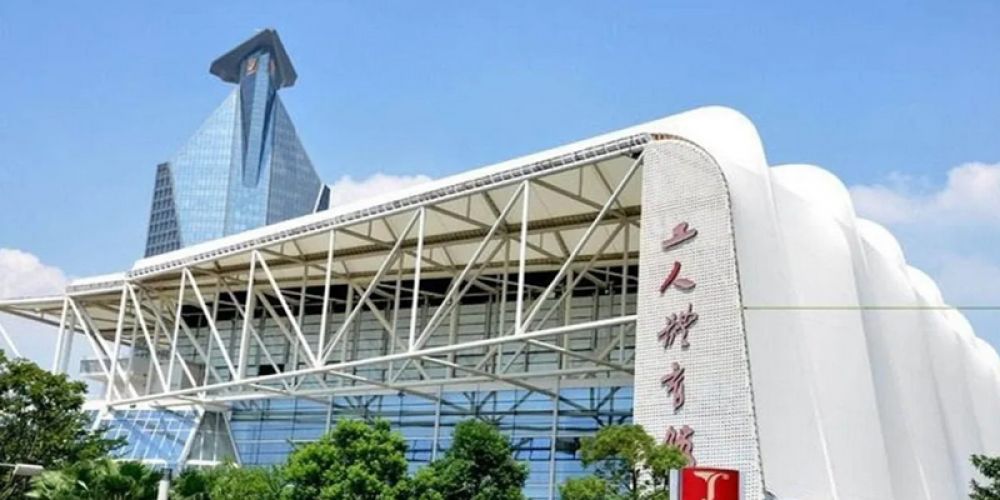

Xiamen Workers’ Gymnasium

- Spanning 80,000 m², it uses large-span steel-frame PTFE membranes to balance structural rigidity, natural lighting, and spatial needs.

-

Kunshan Football Stadium (2023 Asian Cup)

- 45,000-seat venue with a concrete dual-column system and lightweight PTFE membrane.

- Blends rigidity and flexibility, meeting FIFA standards while showcasing modern aesthetics.

Applications of PTFE Membrane Structures

PTFE membranes have become a hallmark of modern architecture since the 1950s. Their lightweight, high strength, durability, and self-cleaning properties make them ideal for stadiums, commercial roofs, and grandstands.

PTFE’s Key Advantages

- Temperature resistance: Stable from -180°C to 260°C.

- Chemical resistance: Insoluble in most solvents.

- Design flexibility: Customizable shapes and sizes.

- Adjustable light transmission: Tailored via thickness and surface treatments.

- Lightweight: Reduces structural load.

- High tensile/tear strength: Supports large spans.

- Energy efficiency: Superior insulation and thermal performance.

- Waterproof and oxidation-resistant: Performs well in harsh environments.

- Self-cleaning surface: Minimizes dust adhesion.

PTFE membrane structures, exemplified by Kunshan Football Stadium, combine functionality with aesthetic innovation, redefining modern architectural possibilities.