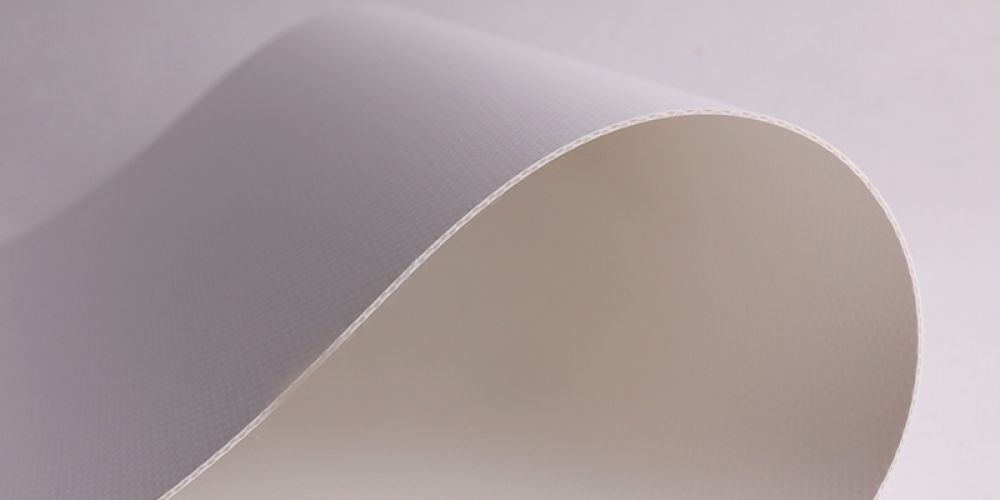

PVC (Polyvinyl Chloride) membrane is the most widely used tensile membrane fabric. PVC is commonly produced in white, but can be produced in a multitude of colours depending on individual project requirements. When produced in white, this flexible fabric membrane reduces radiant heat gain, keeping interior temperatures cooler in warmer environments.

PVC is commonly coated with protective acrylic lacquer, PVDF alloy, 100% PVDF or TiO² coatings. PVDF alloy is made of fluoride, carbon and hydrogen. It has good resistance to airborne pollutants, UV and weather. As the top surface coating is not 100% PVDF it can be easily welded by lap welding.

This material is commonly known as weldable PVDF in today's market and as such it is economical to manufacture and weld. Based on its average self cleaning characteristics the PVC has a design life of approximately 10-15 years.

100% PVDF top coatings offer good self cleaning properties. However, the 100% PVDF coating cannot be welded to another sheet of the same material. The PVDF coating must be ground off or the fabric butt welded. PVC fabrics have excellent fire ratings but are combustible. In general, fire ratings are not a major concern for open structures as the toxic fumes are dispersed by natural ventilation.

When PVC membranes are coated with titanium dioxide (TiO² ) photo-catalyst they inherit self cleaning properties that are superior to conventional PVC coatings. Called the Photo-catalytic decomposition process, a self cleaning action that occurs as the TiO² causes any organic matter (stain or pollutant) to decompose through simple oxidation. The residue does not adhere to the surface and is washed away by water or rain. The Photo-catalytic hydrophilic process, the sheeting action of water across the surface, assures no unsightly streaking is left behind due to water beadi。