TPU Film (Thermoplastic Polyurethanes) vs. TPE Film (Thermoplastic Elastomer Film)

As two distinct polymer materials, TPU and TPE films exhibit significant differences across multiple aspects. Below is a detailed comparison of their characteristics:

TPU Material

TPE Material

Compressive Strength

Hardness

Tactile Feel

Wear Resistance

Rebound Resilience

Fracture Toughness

Manufacturing

Operating Temperature

Applications

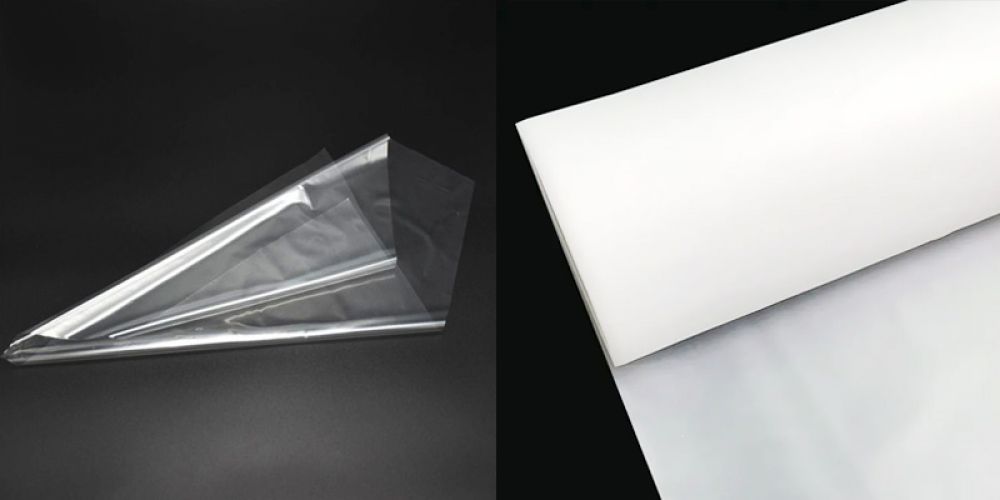

Density and Transparency

Combustion Behavior

Oil Resistance

Shrinkage Rate

TPU and TPE films differ significantly in material structure, physical properties, production, and applications. These distinctions grant each material unique advantages in specific fields. Selection should prioritize application requirements and performance needs.