PTFE (polytetrafluoroethylene) coated fibreglass membranes are composed of a woven glass-fibre base cloth, pre-coated with a silicon layer to prevent moisture absorption, and then coated with liquid PTFE. This process produces a membrane fabric which has low water vapour permeability and excellent UV, anti-adhesive and light translucency properties.

PTFE membrane combines the strength, flexibility, and fire-resistant properties from the fiberglass mesh, with the unrivalled weatherability and chemical resistance from the polytetrafluoroethylene coating. Overall PTFE provides the most aesthetic, durable, low maintenance, and translucent cladding option for membrane structures and tensile architecture solutions and lends itself to many bespoke architectural designs and structural applications.

Conventional PTFE membrane;Shading, low translucency, and porous mesh options are offered to enable architectural design freedom.

Facades & Interiors: Prized for its sound absorption characteristics and fire-resistant qualities, PTFE has the ability to create architecturally stunning facades and interior panelling or soffits. PTFE Mesh is especially suitable for facades, fostering extremely effective light transmission and heat control.

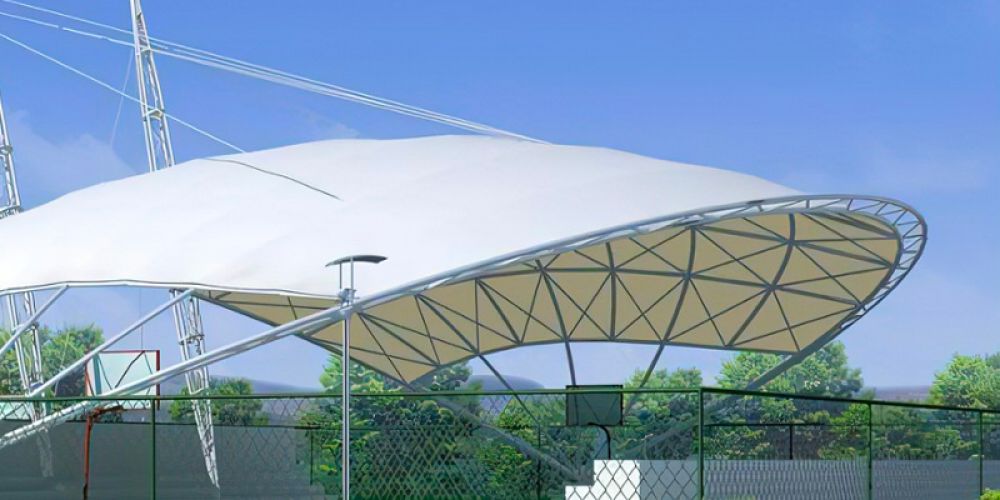

Membrane Roofing: High translucency, strength, aesthetics, and self-cleaning properties of the PTFE membrane make it the perfect membrane for stadium roofs, bowling green canopies, sports court canopies, sporting club grandstands and retail or commercial atrium roofing.

Shade Structures & Awnings: Strong, long-lasting, stable, and with effective protection against UV, PTFE is ideal for retail walkways and shade areas; hotel and restaurant alfresco dining; outdoor buildings for schools and universities, and public transport waiting areas.