The fabric substrate of PTFE film material is glass fiber, the diameter of the fiber should be in the range of 3.30 ~ 4.05μm, and the weight should be greater than 150g/m.

The biggest feature of PTFE film is:

(1) The thickness of PTFE film with high strength and medium strength is only 0.8mm, but its tensile strength has reached the level of steel.

(2) Low elasticity, which is conducive to the formation of complex curved surface modeling of the film.

(3) The use of a wide temperature range, can be used in the temperature range of -70℃ ~ 230℃.

(4) Unique optical properties

During the day, the incident light becomes natural light, preventing glare, no shadow, uniform distribution of light almost no ultraviolet light through, preventing the fading of interior decoration materials and equipment.

At night, its high reflection performance makes the room have excellent lighting effect and reduce electricity consumption.

(5) Good self-cleaning, rain can wash away the surface attachment; Its high light transmittance is 13%, the thermal reflectivity is 73%, the heat absorption is very small, and the general service life is more than 25 years.

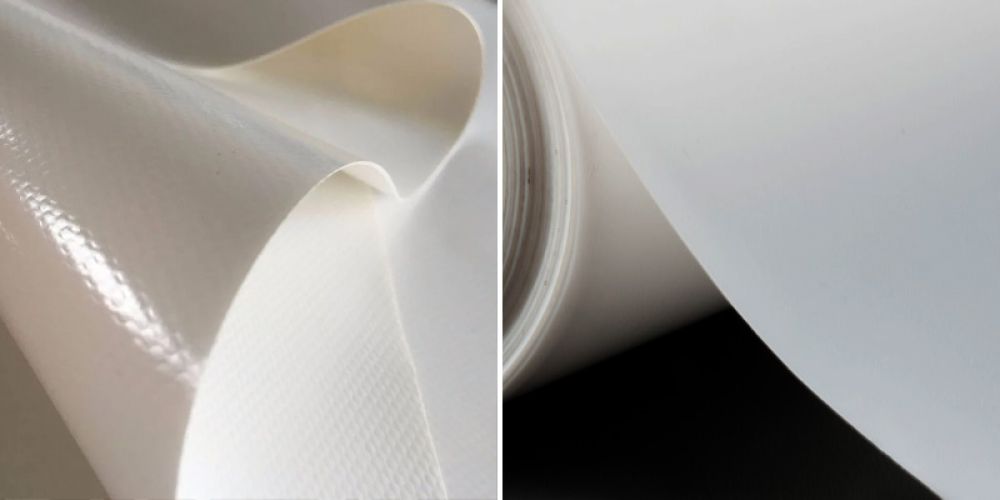

The advantage of PVC film :

PVC film is that it is elastic and cheap, but the disadvantage is that after a certain number of years of use, the elasticity of polyester fiber weakens, resulting in the relaxation of the film cloth and deformation.

PTFE film fabric is glass fiber, high strength and good stability, the disadvantage is easy to break, the way to improve is to make the glass fiber specifications fine. The performance of glass fiber wikis is better than that of polyester fibers.

Another difference between PTFE and PVC films is the coating, which is also the origin of the name of the two. The PVC material itself is poor in ultraviolet resistance, easy to soften under the scorching sun, the temperature difference changes, and its self-cleaning is relatively poor, easy to age and grow mildew, these shortcomings can be compensated by adding specific additives.

PTFE itself is a very stable inert material, self-cleaning performance is good, can absorb ultraviolet light, in the sun will be more and more white, long service life.

In general, PVC in the use of 3-5 years will appear performance degradation until completely aging damage, life in about 10 years; PTFE used 3-5 years of film material is still like new, with 15 years is no problem.

From the material to the process, PTFE is more advanced than PVC, which is also the reason why PTFE performance is significantly better than PVC.