High-frequency (HF) heat sealing machines play a central role in air mattress (inflatable mattress) production. Their technical principle relies on molecular polarization and frictional heating effects induced by high-frequency electromagnetic fields, combined with mold pressure to fuse PVC, TPU, and other flexible plastic films. Below is an analysis of the specific processes, technical advantages, and typical applications:

I. Core Production Process

1. Material Preparation and Cutting

- Air mattress bodies are typically composed of 2–3 layers of PVC or TPU composite film, forming sealed air chambers. Premium products may use flocked PVC surfaces for enhanced tactile comfort.

- Materials are cut to design specifications with welded margins (5–10mm) to ensure bonding strength.

2. High-Frequency Welding (Heat Sealing)

- Equipment Selection:

- High-frequency heat sealers with power ranging from 5,000W to 150kW are selected based on mattress size: large machines for frame welding, compact dual-head machines (5–8kW) for valves and accessories.

- Mold Design:

- Copper or aluminum molds are precision-engineered to match mattress contours. Internal striped patterns enhance bonding strength, while edge molds ensure smooth seams.

- Welding Parameters:

- Current (0.5–10A), pressure (0.2–0.6 MPa), and duration (0.1–10 seconds) are adjusted to control fusion depth and temperature, preventing material scorching or weak joints.

- Automation:

- Auto-frequency tracking stabilizes HF output, while robotic material handling boosts productivity.

3. Valve Welding and Accessory Installation

- Air valves are welded separately using compact dual-head machines for precision and airtightness.

- Post-weld leak testing involves pressure charging (0.02–0.05 MPa, held for 24 hours).

4. Final Inspection and Packaging

- 100% inflation testing checks surface smoothness, seam strength, and airtightness.

- Approved mattresses are folded, compressed, and packaged in protective materials (e.g., nylon bags, oil-resistant paper).

II. Technical Advantages

1. High-Efficiency Bonding and Airtightness

- Molecular fusion via HF welding achieves bond strengths of 2–5 MPa (vs. 0.5–1 MPa for adhesive bonding), with zero VOC emissions.

- Seamless, slag-free joints meet international airtightness standards (e.g., ISO 811, waterproofing ≥30 kPa).

2. Adaptability to Complex Structures

- Large workstations (e.g., 2,100 × 2,300 mm) accommodate mattress frame welding. Mold-swapping enables rapid product changeovers.

- Supports 3D structures (e.g., raised edges, internal support beams) for ergonomic durability.

3. Energy Efficiency and Cost Optimization

- Focused HF energy minimizes thermal loss (30–50% more efficient than hot-plate welding).

- Extended equipment lifespan (8,000–10,000 hours for electronic tubes) lowers maintenance costs for mass production.

III. Typical Applications

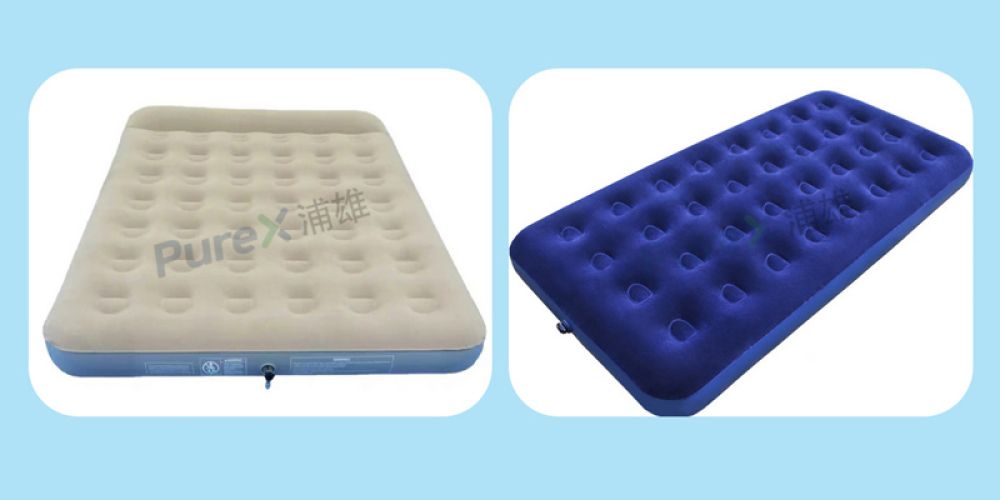

1. Household Air Mattresses

- Single/double-layered designs withstand ≥150 kg loads. Premium variants use triple-layer PVC (flocked surface, reinforcement layer, wear-resistant base) fused via HF welding.

2. Outdoor Inflatable Mattresses

- Rugged designs for camping/water use, with weld joints resistant to extreme temperatures (–20°C to 60°C).

3. Medical Rehabilitation Mattresses

- Anti-decubitus air mattresses feature microporous ventilation structures, welded with ±0.1mm precision for uniform air cell distribution.

4. Customized Air Mattresses

- CAD/CAM-designed molds enable single-step welding of complex shapes (e.g., circular, wave patterns), minimizing post-processing.