PTFE Tensioned Membrane System Applications

1. Mega-Scale Sports Complexes

Implementation Case: Beijing Olympic "Bird's Nest" National Stadium

- Structural Advantage: Utilizes PTFE's ultralong span capacity (>250m unsupported)

- Material Performance: 0.3-1.2mm membrane thickness with 90%+ UV resistance (per ASTM G154)

- Engineering Benefit: Enables column-free roofing (120,000㎡ coverage) maintaining 25% light transmission

2. Permanent Exhibition Architectures

Representative Project: Shanghai World Expo Pavilions

- Optical Efficiency: 12-18% visible light transmission with 92 CRI color rendering

- Maintenance Advantage: TiO₂-coated surface achieves Class A self-cleaning (ISO 27447)

- Durability: 30+ year service life with ≤0.5% annual tensile strength loss

3. Premium Commercial Structures

Typical Installations:

- Airport Terminals: Seamless spans up to 150m (FAA wind load compliant)

- Luxury Retail Complexes: 500-800g/㎡ fabric weight options

- Performance Metric: 1.5kN/m tear strength (EN ISO 1421)

4. Cultural Facilities Enhancement

Lighting Performance:

- Diffuse illumination: 200-500 lux uniformity (CIE 117:1995)

- Thermal Regulation: U-value 0.8W/m²·K (EN 673)

PVC Tensioned Membrane System Applications

1. Community Sports Facilities

Cost-Effective Solution:

- Budget Compliance: $80-120/㎡ installed cost

- Rapid Deployment: 3-5 day installation cycle for 1,000㎡ projects

2. Temporary Event Infrastructure

Operational Advantage:

- Modular Design: 15m×30m standard bay configuration

- Mobility Feature: Complete dismantling <8 hours

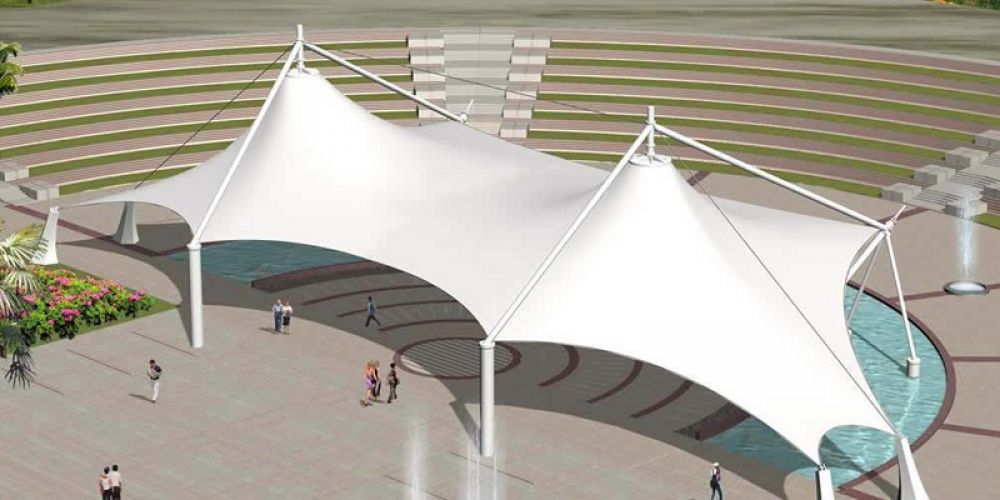

3. Landscape Architecture Elements

Aesthetic Flexibility:

- Color Options: RAL/Toyo 200+ chromatic choices

- Formability: 6-8m minimum curvature radius

4. Agricultural Applications

Agro-Technical Specifications:

- PAR Transmission: 55-70% (400-700nm spectrum)

- Thermal Retention: 4-6°C temperature differential maintenance

- Chemical Resistance: pH 3-11 tolerance (DIN 53378)

Material Performance Comparison

| Parameter |

PTFE Membrane |

PVC Membrane |

| Tensile Strength |

120-180N/cm |

60-100N/cm |

| Fire Rating |

DIN 4102 B1 |

DIN 4102 B2 |

| Service Temperature |

-70°C to +260°C |

-30°C to +70°C |

| Maintenance Cycle |

15-year recoating |

5-year recoating |

For structural engineering calculations or material certification documents (CE/TUV/GB), contact our technical department.