The mobile membrane welding machine is an automated welding device specifically designed for membrane structure engineering (such as architectural membrane materials, air-supported membrane stadiums, inflatable membrane structures, advertising tarpaulins, etc.). Its core function is to achieve efficient and precise splicing of membrane materials through a moving welding head. The following is a detailed analysis of this equipment:

I. Core Functions and Advantages

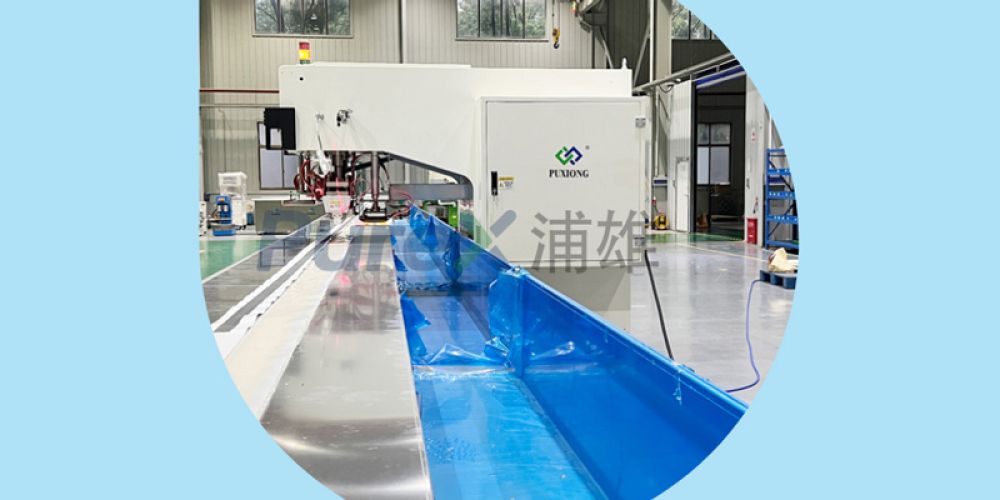

* Automated Mobile Welding: Equipped with an electric or hydraulic drive system, the equipment can move along a preset track or autonomously. The welding head follows the movement to complete welding on straight lines, curves, or complex paths, reducing human error.

* Applicable Scenarios: On-site splicing of large membrane structures (such as stadium stands, air-supported warehouse membranes), or continuous welding of long membrane materials in a factory.

* High-Efficiency Welding Capability: Supports multiple processes such as high-frequency welding, hot air welding, or laser welding. Welding speeds can reach several meters per minute, significantly improving production efficiency.

* High Welding Strength: Meets the tensile and tear resistance requirements of membrane materials.

* Precise Control and Adaptability: Welding temperature, pressure, speed, and other parameters can be adjusted via PLC or CNC system to adapt to membrane materials of different materials (such as PVC, PTFE, ETFE) and thicknesses. Equipped with sensors to monitor welding quality in real time and automatically correct deviations.

Portability and Flexibility: Modular design for easy disassembly, assembly, and transportation, suitable for on-site operations (such as at heights or in complex terrain).

Some models support wireless remote control operation, enhancing operational safety.

II. Technical Parameters and Structure

Key Parameters:

Welding Width: Typically 10-50mm (adjustable depending on membrane material type).

Traveling Speed: 0.5-10m/min (adjustable).

Power Supply: 220V/380V, power varies depending on the welding process (high-frequency welding requires higher power).

Weight: 50-300kg (lightweight design for easy movement).

Core Structure:

Traveling Mechanism: Wheeled or rail-mounted, equipped with a drive motor and guide wheels.

Welding Head: Integrated heating element (such as high-frequency electrode, hot air gun) or laser emitter.

Control System: Touch screen or CNC panel, supporting parameter storage and retrieval.

Auxiliary Devices: Pressure wheels, cooling system, dust removal device (optional). III. Application Scenarios

* **Architectural Membrane Structures:** Splicing of membrane roofs for stadiums, exhibition centers, airport terminals, etc.

Example: Welding of the ETFE membrane structure in Beijing's "Water Cube".

* **Air-supported Membrane Venues:** On-site welding of inflatable membrane structures (such as warehouse air-supported membranes and sports air-supported membranes).

* **Advertising and Tarpaulins:** Splicing and repair of large advertising fabrics, tents, and tarpaulins.

* **Industrial Applications:** Welding of environmental protection equipment (such as membrane covers for sewage treatment plants) and agricultural greenhouse films.