High-frequency membrane heat sealing machines are key equipment in the field of membrane structure construction. Their technical principle is based on high-frequency electromagnetic field heating, achieving efficient and precise connection of membrane materials through a non-contact heating method. This article will analyze the technical characteristics of high-frequency membrane heat sealing machines from three aspects: technical principle, core advantages, and application scenarios.

The technical principle of high-frequency membrane heat sealing machines can be summarized in four steps: electromagnetic induction, molecular friction, localized melting, and pressure bonding.

First, a high-frequency current generates a high-frequency changing electromagnetic field (typically between 27MHz and 40MHz) through electrodes.

Second, the electromagnetic field causes polar molecules in the membrane material (such as chlorine atoms in PVC coatings) to vibrate violently and generate heat through friction.

Subsequently, the heat concentrates in the contact area of the membrane material, causing the localized material to rapidly reach a molten state.

Finally, uniform pressure is applied through a pressure system, causing the molten material to cool and solidify, achieving a strong connection.

This process requires no external heat source, has a fast heating speed (usually completed within 1-3 seconds), and the heating area is precisely controllable, avoiding material deformation or scorching problems caused by traditional hot air guns or soldering irons.

The core advantages of high-frequency membrane heat sealing machines are reflected in four aspects:

First, uniform heating. The high-frequency electromagnetic field causes the molecules inside the membrane to vibrate synchronously, resulting in uniform heat distribution and preventing material degradation caused by localized overheating.

Second, high welding strength. High-frequency heat sealing achieves material connection through molecular-level bonding, with welding strength approaching or exceeding that of the parent material.

Third, adaptability to complex structures.

Fourth, environmental protection and energy saving. High-frequency heat sealing is a non-contact heating method, requiring no glue or solvents, thus avoiding the emission of volatile organic compounds (VOCs) and meeting green building standards.

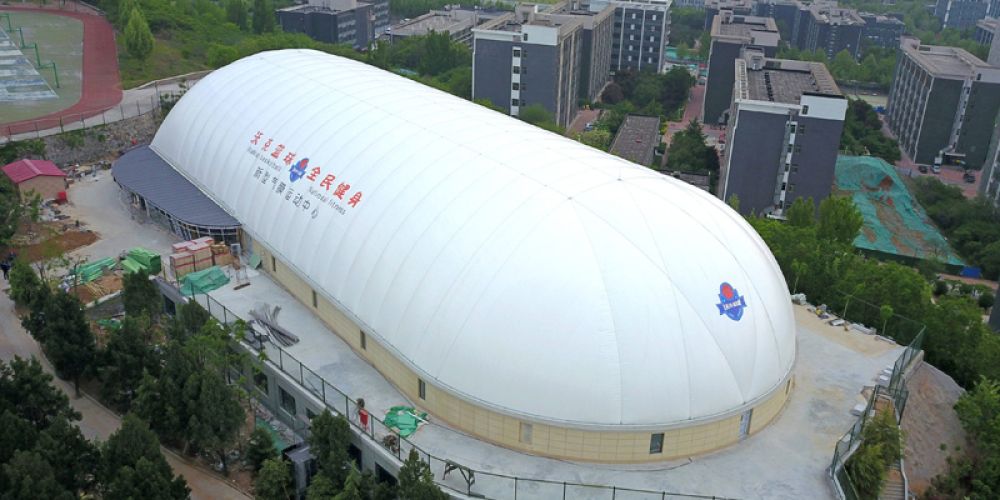

High-frequency membrane heat sealing machines have a wide range of applications, covering sports stadiums, transportation hubs, environmental protection facilities, commercial spaces, and other fields.

In sports stadiums, high-frequency heat sealing machines are used for splicing and sealing the edges of roof membrane materials, ensuring the airtightness and durability of the structure.

In transportation hubs, they are used for welding platform sunshades and inflatable membrane structures, improving construction efficiency and safety.

In environmental facilities, high-frequency heat sealing machines achieve seamless connections between sewage treatment plant membranes and landfill geomembranes, preventing leakage and pollution.

In commercial spaces, they are used for the rapid construction of temporary exhibition tents and outdoor billboards, meeting flexible and ever-changing market demands.

With its unique technical principles and core advantages, the high-frequency membrane heat sealing machine has become an indispensable key piece of equipment in the field of membrane structure architecture. As membrane structure architecture develops towards larger spans, more complex shapes, and higher environmental standards, the high-frequency membrane heat sealing machine will continue to innovate, providing modern buildings with more efficient, reliable, and environmentally friendly connection solutions.