Tarps are versatile and useful products for various industries. How to connect two pieces of waterproof, used to make both waterproof and sunshade products.

Tarp welding machines have a wide range of uses in various industries:

Construction and renovation: Tarps protect materials on construction sites from the weather. Welding machines connect tarps to protect them from rain, wind and sunlight.

Transportation: Trucks and trailers use tarps to secure their cargo. Welding ensures they can withstand rough roads and conditions.

Agriculture: Tarps protect crops from the weather and act as cover for agricultural tunnels. The tarp can be easily attached by welding where needed.

Gardening: Tarps protect plants from frost, pests, and excessive sunlight. Solder the precise connection of the tarp, which is essential for complex shapes.

How do tarpaulin materials bond?

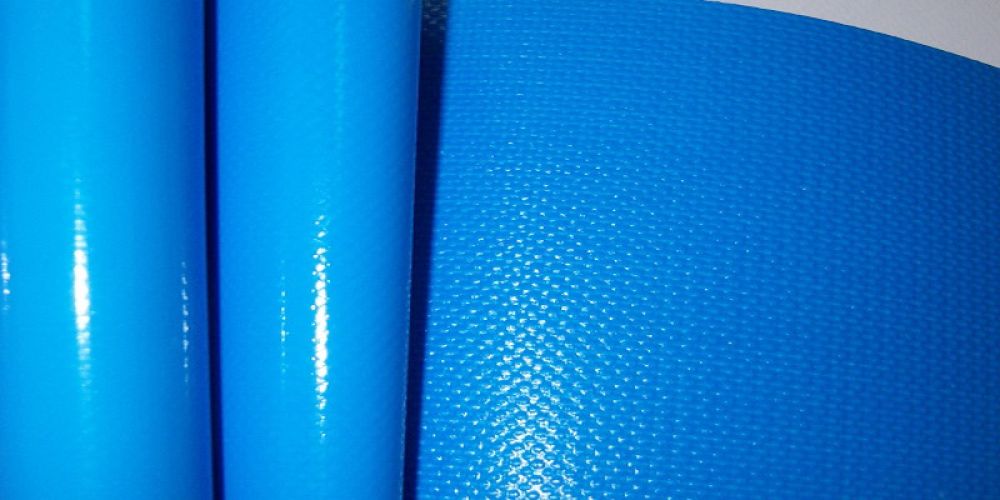

The manufacture of tarps and coverings continues to evolve with technology for efficiency and durability. Previously, tarps were sewn, but today, a welding machine is necessary. PVC is a common tarpaulin material, tear resistant, weather resistant. Ultraviolet radiation will make it fade, but modern PVC film technology adds ultraviolet filters. High frequency welding is an effective way to connect PVC.

Advantages of high frequency machine in welding tarps:

Strong welding: Welding forms a durable tarp connection, extending the service life of the material.

Cost saving: manual tarpaulin connection speed is slow; Welding automates the entire process, saving time and effort.

Beautiful appearance: Welding ensures a precise, uniform connection, resulting in an attractive final product.

Safe and reliable: welding safety, hot air welding does not produce smoke or PVC smoke.